Alumina Ceramic Grinding Ball

Chemshun Ceramic Product Foardielen

1) Excellent wear en abrasion beskerming eigendom

2) Legere produksje- en ûnderhâldskosten

3) Excellent corrosie ferset eigendom

4) Poerbêst effekt ferset eigendom

5) Excellent waarmte ferset eigendom

6) Maklik te behanneljen grutte en gewicht

7) Fluch en feilige ynstallaasje

Technyske data

| S.No. | Attributen | Ienheid | CHEMSHUN 92 I | CHEMSHUN92 II | CHEMSHUN 95 | CHEMSHUN ZTA |

| 1 | Alumina ynhâld | % | 92 | 92 | 95 | 70-75 |

|

| ZrO2 | % |

|

|

| 25-30 |

| 2 | Tichtheid | g/cc | ≥3,60 | ≥3,60 | >3.65 | ≥4.2 |

| 3 | Kleur | - | Wyt | Wyt | Wyt | Wyt |

| 4 | Wetter Absorption | % | <0.01 | <0.01 | 0 | 0 |

| 5 | Flexural sterkte | Mpa | 270 | 300 | 320 | 680 |

| 6 | Moh's Density | Klasse | 9 | 9 | 9 | 9 |

| 7 | Rock Well Hardness | HRA | 80 | 85 | 87 | 90 |

| 8 | Vickers hurdens (HV5) | kg/mm2 | 1000 | 1150 | 1200 | 1300 |

| 9 | Fracture Toughness (Min) | MPa.m1/2 | 1000 | 3-4 | 3-4 | 4-5 |

| 10 | Compressive sterkte | Mpa | 850 | 850 | 870 | 1500 |

| 11 | Termyske útwreidingskoëffisjint | 1x10-6/ºC | 8 | 7.6 | 8.1 | 8.3 |

| 12 | Maksimum operaasje temperatuer | ºC | 1450 | 1450 | 1500 | 1500 |

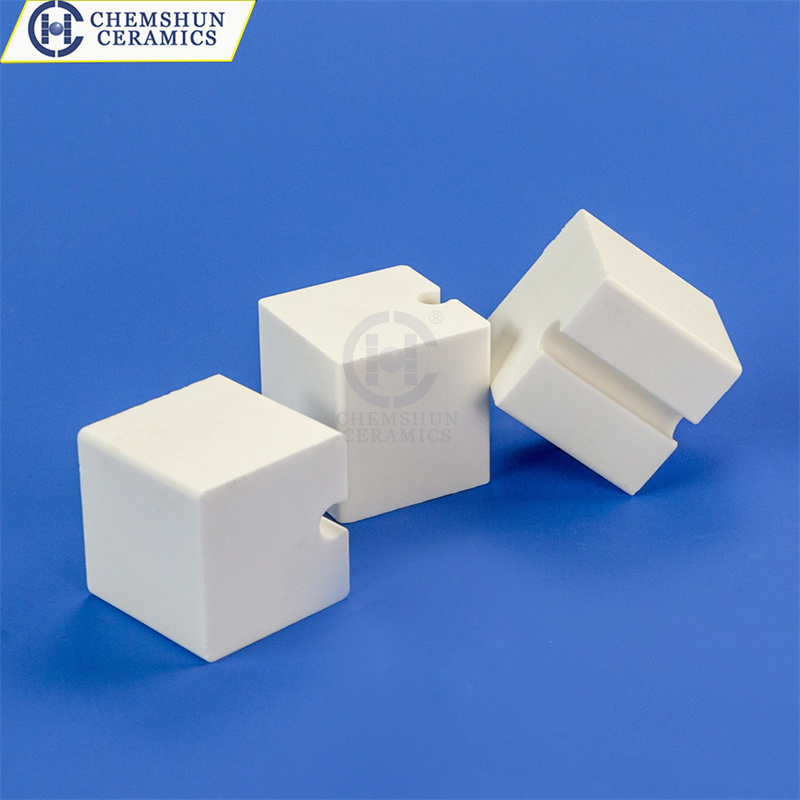

Grutte

| Beskikbere grutte fan Inter-locking tegel út Chemshun | ||

| Lengte (mm) | Breedte (mm) | Dikte (mm) |

| 100 | 33 | 25 |

| 50 | 20/19.28 | 5 |

| 40 | 40 | 10/25/40/50 |

| 40 | 20 | 25/50 |

| 38 | 38 | 38 |

| 32 | 32 | 16/32 |

| 30 | 30 | 25 |

| 30 | 15 | 25 |

Wy hawwe mear as 1000 set fan keramyske mallen.D'r binne in protte oare soarten en grutte keramyske blokprodukten.Foar mear ynformaasje, wolkom om kontakt mei ús op.

Oanfraach

| Applikaasje Yndustry út Chemshun | ||

| Yndustry | Equipment System | Equipment dielen |

| Semint | Pre-blend systeem foar crashing kalkstien en rûge brânstof | Chute, Bunker, Katrol lagging, ûntslachkegel |

| Raw molen systeem | Feed chute, Retaining ring, Scraper plaat, Seal ring, Pipeline, Emmer guard, Cyclone, Poeder concentrator body, Bunker | |

| Cement mole systeem | Chute, Bunker, Fan vane wheel, Fan casing, Cyclone, Circular duct, Conveyer | |

| Ball molen systeem | Pulverizer exhauster lichem en vine tsjil, Poeder concentrator syn lichem, Pulverized stienkoal syn pipeline, Hot lucht duct | |

| Sintersysteem | Inlet / Outlet bocht, Wind wearde plaat, Cyclone, Chute, Stofsamler syn pipe | |

| Afterheat systeem | Pipeline en muorre fan separator | |

| Stiel | Raw materiaal feeding systeem | Hopper, Silo |

| Batching systeem | Mingbunker, Mixing barrel, Mixing Disk, Disk pelletizer | |

| Sintered materiaal ferfier systeem | Hopper, Silo | |

| Dedusting en Ash discharge systeem | Dedusting pipeline, Bend, Y-stik | |

| Koksysteem | Coke hopper | |

| Middelsnelle mole | Kegel, skiedingsbuffels, Outlet pipe, Pulverized stienkoal syn pipeline, Burner cone | |

| Ball mole | Classifier, Cyclone separator, Bend, Poeder concentrator's Binnenshell | |

| Termyske krêft | Coal handling systeem | Bucket wheel machine, Coal Hopper, Coal Feeder, Orifice |

| Ball molen systeem | Separator syn piip, elmboog en kegel, Coal mill syn elbow en rjochte buis | |

| Middelsnelle mole | Coal mill body, skiedingsbuffels, kegel, pipeline, elbow | |

| Fall mole | Pulverized stienkoal syn Pipeline en Elbow | |

| Dedusting systeem | Dedusting's Pipeline en Elbow | |

| Ash discharge systeem | Fan duster's shell, Pipeline | |

| Haven | Transport materiaal systeem | Skiif en hopper fan bakwielmasine, hopper fan oerdrachtpunt, hopper fan unloader, |

| Smelting | Transport materiaal systeem | Meethopper, Coke hopper, Trillende skerm's chute, Head valve, Intermediate Bin, Tail bin |

| Batching systeem | Batch hopper, Mixing masine | |

| Burning systeem | Ash emmer, Pomp calcine buis, Hopper | |

| Dedusting systeem | Dedusting's Pipeline en Elbow | |

| Gemysk | Transport materiaal systeem | Hopper, Silo |

| Dedusting systeem | Dedusting's Pipeline en Elbow | |

| Ferwurkjen apparatuer | Vibromill liner | |

| Koal | Coal handling systeem | Bucket wheel machine, Coal Hopper, Coal Feeder, Silo |

| Koal wasksysteem | Hydrocyclone | |

| Mynbou | Transport materiaal systeem | Hopper, Silo |

Betsjinning

Wy akseptearje oanpaste oarders.

As jo mear produktynformaasje wolle witte, nim dan gerêst kontakt mei ús op en wy sille jo it meast geskikte produkt en de bêste tsjinst leverje!