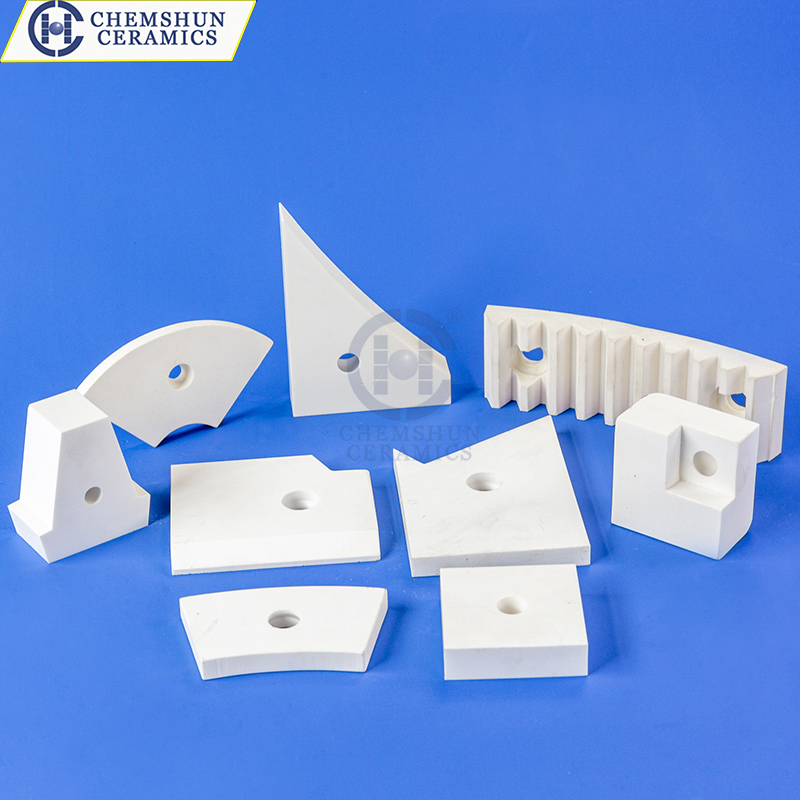

Alumina Ceramic Wear Plate foar Yndustry Underhâld

Eigenskip

· Excellent corrosie ferset eigendom

· Maklik te behanneljen grutte en gewicht

· Excellent waarmte ferset eigendom

· Excellent ynfloed ferset eigendom

· Snelle en feilige ynstallaasje

· Legere produksje- en ûnderhâldskosten

Chemshun Ceramic Foardielen

· Profesjoneel technysk team om CAD-ûntwerpen te beteljen

· Profesjoneel ynstallaasjeteam om ynstallaasjetsjinst te beteljen

· Goed fêststeld proses neffens ynternasjonale noarmen

· Akseptearje de standert en foarôfgeande tegels

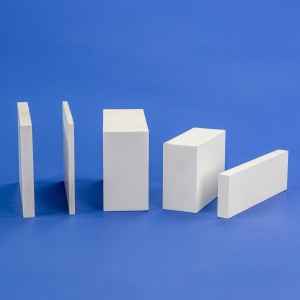

Ofmjittings

| ITEM NO. | PRODUKT | LENGTE x WIDTH | DIKKE | Q'TY PER BOX |

| mm | mm | pcs | ||

| 1 | PLAIN TILE | 100 x 100 | 6 | 50 |

| 2 | PLAIN TILE | 100 x 100 | 12 | 20 |

| 3 | PLAIN TILE | 100 x 100 | 15 | 15 |

| 4 | PLAIN TILE | 100 x 100 | 25 | 10 |

| 5 | PLAIN TILE | 100 x 100 | 50 | 5 |

| 6 | PLAIN TILE | 100x25 | 6 | 135 |

| 7 | PLAIN TILE | 150 x 100 | 6 | 50 |

| 8 | PLAIN TILE | 150 x 100 | 12 | 20 |

| 9 | PLAIN TILE-GLAZED | 150 x 100 | 12 | 20 |

| 10 | PLAIN TILE | 150 x 100 | 15 | 15 |

| 11 | PLAIN TILE | 150 x 100 | 25 | 10 |

| 12 | PLAIN TILE-GLAZED | 150 x 100 | 25 | 10 |

| 13 | PLAIN TILE | 150 x 100 | 50 | 5 |

| 14 | PLAIN TILE | 150 x 50 | 12 | 40 |

| 15 | PLAIN TILE | 150 x 50 | 25 | 20 |

| 16 | PLAIN TILE | 150 x 25 | 6 | 135 |

| 17 | PIPE TILE | 150 x 31/35 | 12 | 57 |

| 18 | PIPE TILE | 150 x 39/42 | 12 | 40 |

| 19 | PIPE TILE | 150 x 50/53 | 12 | 40 |

| 20 | PIPE TILE | 150 x 45/47 | 12 | 40 |

| 21 | PIPE TILE | 150 x 27/35 | 25 | 20 |

| 22 | PIPE TILE | 150 x 35/42 | 25 | 20 |

| 23 | PIPE TILE | 150 x 47/53 | 25 | 20 |

| 24 | PIPE TILE | 150 x 43/47 | 25 | 20 |

| 25 | PIPE TILE | 150 x 43/47 | 50 | 10 |

| 26 | LASBARE TEGELS | 100 x 100 | 12 | 20 |

| 27 | LASBARE TEGELS | 100 x 100 | 15 | 16 |

| 28 | LASBARE TEGELS | 100 x 100 | 25 | 10 |

| 29 | LASBARE TEGELS | 100 x 100 | 50 | 5 |

| 30 | LASBARE TEGELS | 150 x 100 | 12 | 20 |

| 31 | LASBARE TEGELS | 150 x 100 | 15 | 16 |

| 32 | LASBARE TEGELS | 150 x 100 | 25 | 10 |

| 33 | LASBARE TEGELS | 150 x 100 | 50 | 5 |

Applikaasje yn Industries

| Yndustry | Equipment systeem | Equipment dielen |

| Semint | Pre-blend systeem foar crashing kalkstien en rûge brânstof | Chute, bunker, pulley lagging, ûntslachkegel |

| Raw molen systeem | Feed chute, retining ring, scraper plate, seal ring, pipeline, emmer guard, cycloon, poeder concentrator body, bunker | |

| Cement mole systeem | Chute, bunker, fan vaanwiel, fan casing, cycloon, circular duct, conveyer | |

| Ball molen systeem | Pulverizer exhauster lichem en vine tsjil, poeder concentrator syn lichem, pulverized stienkoal syn pipeline, hite lucht duct | |

| Sintersysteem | Inlet/outlet bocht, wyn wearde plaat, cycloon, chute, stofsamler syn piip | |

| Afterheat systeem | Pipeline en muorre fan separator | |

| Stiel | Raw materiaal feeding systeem | Hopper, silo |

| Batching systeem | Mixing bunker, mix barrel, mix disk, disk pelletizer | |

| Sintered materiaal ferfier systeem | Hopper, silo | |

| Dedusting en Ash discharge systeem | Dedusting pipeline, bocht, y-stik | |

| Koksysteem | Coke hopper | |

| Middelsnelle mole | Kegel, skiedingsbuffels, útlaatpipe, pipeline fan poederkoal, burnerkegel | |

| Ball mole | Classifier, cycloon separator, bocht, poeder concentrator syn ynderlike shell | |

| Termyske krêft | Coal handling systeem | Bucket tsjil masine, stienkoal hopper, stienkoal feeder, orifice |

| Ball molen systeem | Separator syn piip, elbow en kegel, koale mole syn elbow en rjochte buis | |

| Middelsnelle mole | stienkoal mole lichem, skieding buffles, cone, pipeline, elbow | |

| Fall mole | Pulverized stienkoal syn pipeline en elbow | |

| Dedusting systeem | Dedusting syn pipeline en elbow | |

| Ash discharge systeem | Fan duster syn shell, pipeline | |

| Haven | Transport materiaal systeem | Skiif en hopper fan bakwielmasine, hopper fan oerdrachtpunt, hopper fan losser, |

| Smelting | Transport materiaal systeem | Mjittrechter, coke hopper, trillende skerm's chute, kopklep, Intermediate bin, tail bin |

| Batching systeem | batch hopper, mingde masine | |

| Burning systeem | Jiskemmer, pomp calcine buis, hopper | |

| Dedusting systeem | Dedusting syn pipeline en elbow | |

| Gemysk | Transport materiaal systeem | Hopper, silo |

| Dedusting systeem | Dedusting syn pipeline en elbow | |

| Ferwurkjen apparatuer | Vibromill liner | |

| Koal | Coal handling systeem | Bucket tsjil masine, stienkoal hopper, stienkoal feeder |

| Koal wasksysteem | Hydrocyclone | |

| Mynbou | Transport materiaal systeem | Hopper, silo |

Technyske gegevensblêd

| S.No. | Attributen | Ienheid | CHEMSHUN 92 I | CHEMSHUN92 II | CHEMSHUN 95 | CHEMSHUN ZTA |

| 1 | Alumina ynhâld | % | 92 | 92 | 95 | 70-75 |

| ZrO2 | % | 25-30 | ||||

| 2 | Tichtheid | g/cc | ≥3,60 | ≥3,60 | >3.65 | ≥4.2 |

| 3 | Kleur | - | Wyt | Wyt | Wyt | Wyt |

| 4 | Wetter Absorption | % | <0.01 | <0.01 | 0 | 0 |

| 5 | Flexural sterkte | Mpa | 270 | 300 | 320 | 680 |

| 6 | Moh's Density | Klasse | 9 | 9 | 9 | 9 |

| 7 | Rock Well Hardness | HRA | 80 | 85 | 87 | 90 |

| 8 | Vickers hurdens (HV5) | kg/mm2 | 1000 | 1150 | 1200 | 1300 |

| 9 | Fracture Toughness (Min) | MPa.m1/2 | 1000 | 3-4 | 3-4 | 4-5 |

| 10 | Compressive sterkte | Mpa | 850 | 850 | 870 | 1500 |

| 11 | Termyske útwreidingskoëffisjint (25-1000ºC) | 1×10-6/ºC | 8 | 7.6 | 8.1 | 8.3 |

| 12 | Maksimum operaasje temperatuer | ºC | 1450 | 1450 | 1500 | 1500 |

Produkt Tags

Skriuw jo berjocht hjir en stjoer it nei ús